FERMENTER is a special tank used for the fermentation of mash from red grapes.

Fermenters are equipped with an active submerging of the cap of the pomace. According to the system we offer four types of fermenters. Fermenters with Inclined stirrer, rotating fermenters, piston fermenters and sprinkling fermenters. Fermentation process is monitored and controlled by computer on wich we set up required temperature of mash and the intervals of submerging of the cap of pomace

We produce tanks exactly on customer request and demands.

FERMENTERS WITH INCLINED STIRRER

- stirring of the pomace cap by using inclined stirrer

- Tank is equipped with inclined stirrer

- bottom is conical or inclined with gradient from 5 to 35 %, eventually on the bottom is installed electric pushing mechanism

- the warming of mash is provided by a double bottom with electric warming or double jacket

- the cooling of the mash is solved with a cooling double jacket or board exchanger

- cylinder part of the tank can be supplied in wooden design

- positions and dimensions of manholes, gates and valves are designed according to the customer´s demands

SPRINKLING FERMENTER

- sprinkling of the pomace cap by using a mash pump

- Tank is equipped with fixed or rotating sprinkling system and its own o an external pump wich is used for pumping of mash

- bottom is conical or inclined with gradient from 5 to 35 %, eventually on the bottom is installed electric pushing mechanism

- the warming of mash is provided by a double bottom with electric warming or double jacket

- the cooling of the mash is solved with a cooling double jacket or board exchanger

- cylinder part of the tank can be supplied in wooden design

- positions and dimensions of manholes, gates and valves are designed according to the customer´s demands

ROTATING FERMENTERS

- stirring of the pomace cap by using rotating arms

- horizontal or cylinder tank

- equipped with electrically-powered stirring arms

- vertical tank has a conical or inclined bottom with a gradient from 5 to 35%, eventually on the bottom is installed electric pushing mechanism

- horizintal tank is empted with stirring arms

- warming of the mash is provided by a double bottom with electrical warming or double jacket

- the cooling of the mash is solved with a cooling double jacket or board exchanger

- positions and dimensions of manholes, gates and valves are designed according to the customer´s demands

PISTON FERMENTER

- stirring of the pomace cap by using pneumatick pistons

- tak is equipped with one or two pneumatic pistons with immersion components

- the piston version can be combine with the sprinkling system

- vertical tank has a conical or inclined bottom with a gradient from 5 to 35%, eventually on the bottom is installed electric pushing mechanism

- warming of the mash is provided by a double bottom with electrical warming or double jacket

- the cooling of the mash is solved with a cooling double jacket or board exchanger

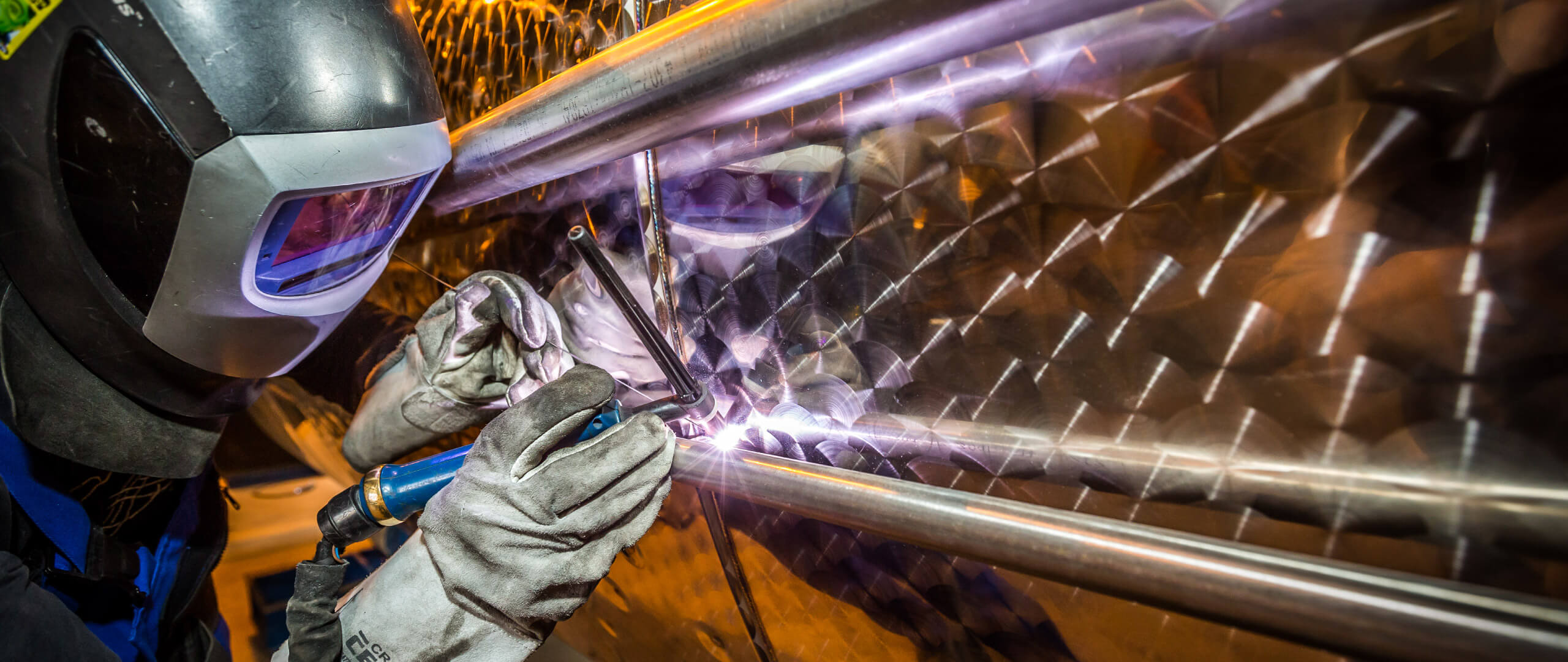

Fermenters are made from AISI 304 material. Fermenters can be made from AISI 316 material if requested.